The multi-faceted nature of our equipment enables us to offer virtually all technically feasible radiographic inspections that are requested according to international standards.

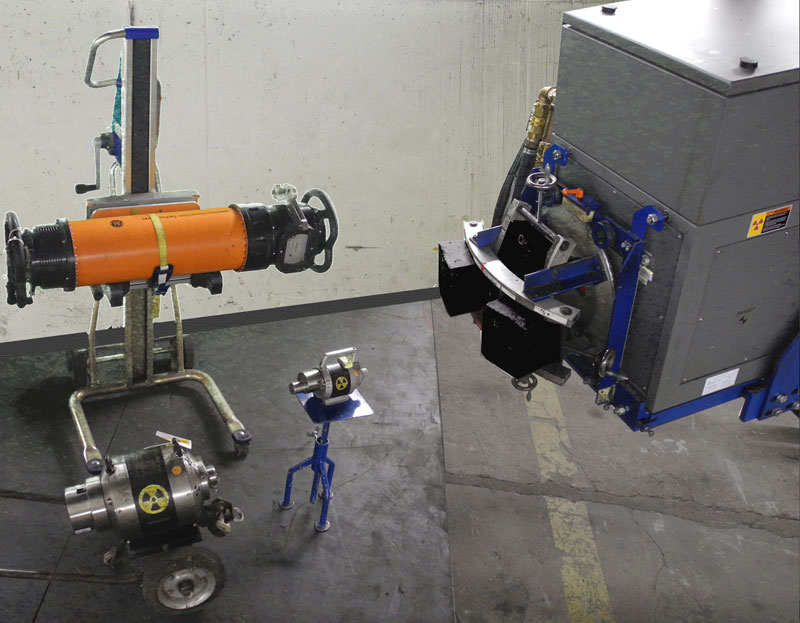

We have a total of 16 radiation sources ranging from minifocus X-ray tubes, radioisotopes and 450 kV systems to our 9 MeV linear accelerator. This enables us even to cover test areas that others refer to as 'technically not testable'.

Areas that are difficult to access can be tested with Ir192, Co60 isotopes or with our panorama X-ray tube.

Castings with dimensions of several metres weighing dozens of tons can be loaded into our 25 metre long testing hall using our 50-ton crane, where they can be set up in readiness for inspection. Steel wall thicknesses of up to 300 mm are routine matters for us. Single exposures take just a few minutes.

With nine radiation protection rooms resp. cabins, and a total of five film development machines, we keep redundant capacity on hand to handle a variety of orders to be processed parallel to one another, or to enable serial testing.

We also operate a film scanner and a digital detector system, meaning that we are also well equipped in terms of digital technology.